Baby boilers help in maintaining a hygienic environment within the tea processing units, especially in the manufacturing of Green Tea. These machines help to clean and eradicate bacteria from tea processing areas and machineries.

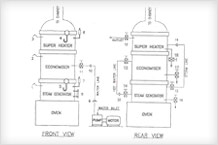

| FRONT VIEW |

REAR VIEW |

| 1-3 TEST COCKS |

9 FOOT VALVE |

| 4-5 PRESSURE GAUGE |

11,12,15 WHEEL VALVE |

| 6-7 SAFETY VALVE |

10,19,20 NON-RETURN VALVE |

| 8 WATER GAUGE GLASS |

16-18 OUTLET DRAIN |

Filling Water

- Open : 1,11,13,14,15

- Close : 2,3,12,16,17,18

- Start the pump.

- Stop the pump when water level in gauge glass (8)

is about 1" from top.

- Close 1 & 11.

Shutting Down

- Stop firing the boiler.

- Open 3, close 12, open 18.

- Fill water upto the highest level (gauge 8) with no gap from top.

- As the boiler cools down leave 3 & 18 open.

Heating, Charging & Operation

- Start firing the boiler.

- When Pressure gauge (5) reaches 15/20 Lbs/in open test cock (1)

for few minutes & then close (1).

- When pressure gauge (5) reaches 70 Lbs/in open steam outlet (12) slowly in stages (3 stages) to warm up the line. Finally when pressure gauge (5) reaches 100 Lbs/in, the system is ready to deliver steam. During steam delivery and operation check water level (8) continuously and add water (open 11 & start pump) until water level in gauge glass (8) is about 1" from top (close 11 & stop pump)

Click here to contact us